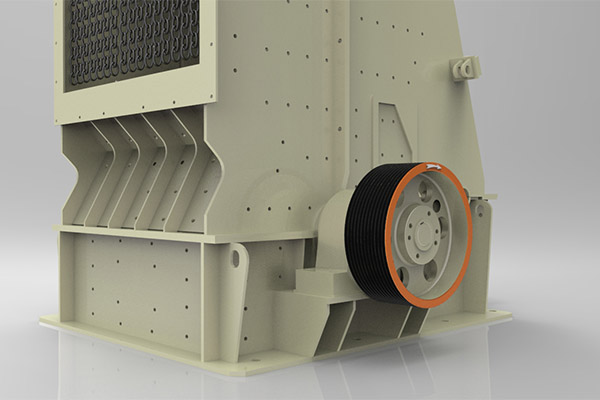

PFS series vortex strong impact crusher is high efficient impact crusher developed by our company. This crusher is applied to coarse and fine crushing of a variety of materials with compression strength not more than 250Mpa. It has the features of unique structure, easy operation, high-efficiency and saving energy, good product shape-cubic, adjustable discharge size, simplifying crushing process, saving cost etc. It can be widely used in electricity, water, highway artificial aggregate crushing industry and so on.

1.The special designed vortex crushing chamber and P, S, T three crushing area can ensure higher crushing ratio, smaller discharge size and better finished product shape.

2.The jagged impact plate will produce a bending broken force when raw materials strike, and it’s crushing ability is better than flat impact plate.

3.Reliable protective device for overload and entering iron: T crushing chamber possesses elastic device which have the buffered and compressive function.

4.Heavy-duty designed rotor can improve reliability and rotational inertia to promote the processing capacity of crusher.

5.Rotor body is joined with rotor shaft by taper sleeve to make sure convenient disassembly and wile versatility. Hammerhead is fixed by wear-resisted wedge block with inserted installation, and it features in easy installation, quick replacement and automatic chucking in running.

6.Plate hammer can be replaced in vertical and horizontal direction to ensure machines is suitable for variety applications.

7.The hydraulic device can open rear frame automatically for inspection, maintenance and adjust discharge size. Thus the downtime is reduced dramatically.

8.Adopting bearing automatic lubrication system and bearing temperature sensor can guarantee the safety of bearing and sharply increase the maintenance cycle.

9.Single driving series products can equip rotor automatic revolving system and rotor can be positioned at any direction when you replace hammer bars or adjust impact plates.

10.The sensor on frame can avoid accident starting during maintenance, thus the security can be guaranteed.

11.Due to the wide application of the wearing parts, the common spare parts are only 2-3 kinds. Hammer bar have two impact surfaces, the use ratio up to 56%.

| Model | Max. feeding Size(mm) | Discharge Size (mm) | Capacity (t/h) |

Power (kw) |

Outline Size (mm) | Weight (kg) | |

| -150MPa | -250MPa | ||||||

| PFS0808 | 200 | 150 | -25(80-90%) | ~46 | ~55 | 1900×1860×2150 | 8800 |

| PFS1108 | 300 | 180 | -30(80-90%) | ~80 | ~90 | 2845×2148×2262 | 11079 |

| PFS1110 | 400 | 200 | -35(80-90%) | ~112 | ~110 | 2845×2360×2262 | 13510 |

| PFS1113 | 400 | 200 | -40(80-90%) | ~150 | ~320 | 28450×2719×2262 | 16050 |

| PFS1310 | 500 | 250 | -40(80-90%) | 180 | ~160 | 3913×2511×2925 | 20095 |

| PFS1313 | 600 | 250 | -40(80-90%) | 225 | ~220 | 3913×2719×2925 | 22650 |

| PFS1315 | 700 | 300 | -50(80-90%) | 280 | ~280 | 3913×2969×2925 | 25500 |

| PFS1320 | 700 | 300 | -50(80-90%) | 350 | 2×200 | 3913×3402×2925 | 32386 |

| PFS1515 | 1000 | 350 | -50(80-90%) | 400 | 2×220 | 4310×3330×3660 | 39000 |

| PFS1520 | 1000 | 400 | -50(80-90%) | 500 | ~2×280 | 4310×3330×3660 | 42000 |

| PFS1720 | 1300 | 450 | -50(80-90%) | 580 | ~2×315 | 5540×3830×4600 | 57000 |

| PFS1725 | 1300 | 500 | -50(80-90%) | 670 | ~2×355 | 5540×4330×4600 | 66000 |

Electrical motor drives through V-belts and makes the rotor run at high speed. Materials will be fed into the crushing chamber from feed inlet, and be struck by the plate hammer which rotates at high speed. The materials are thrown up to the dentate reaction plate on the top of the crushing chamber and then falls down, the thrown-up and falling-down materials are crushed by striking with each other. The big incompletely crushed materials will form big stress and bending force at the interaction of hammer and thick impact plate in P crushing chamber, even the hard crushed materials will be broken and enter into the following S and T crushing chamber. The materials in these two crushing chambers can be medium and fine crushed by striking, impacting, bending and extruding, then discharged out of the machine.

Leave message

Please Feel free to give your inquiry in the form below.We will reply you in 24 hours.