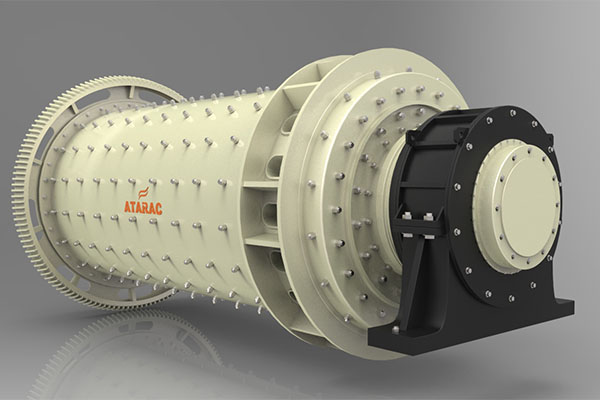

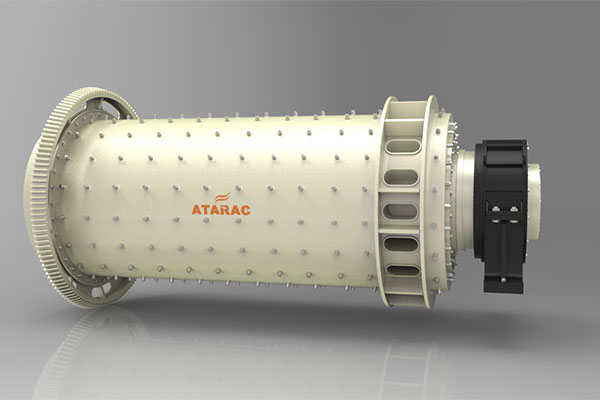

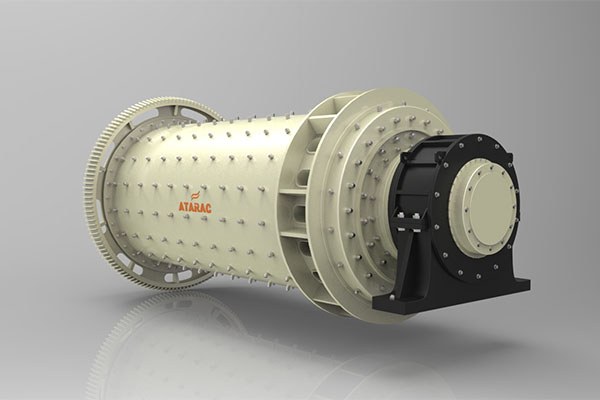

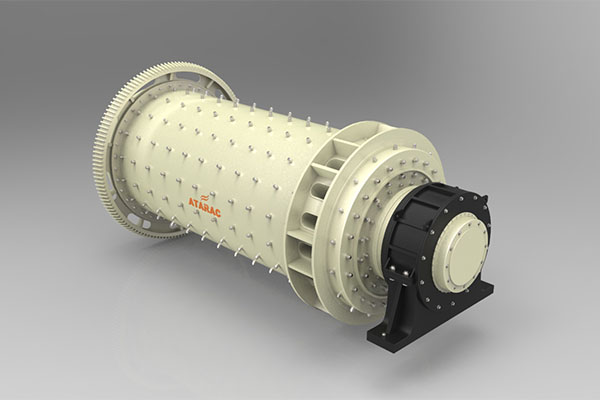

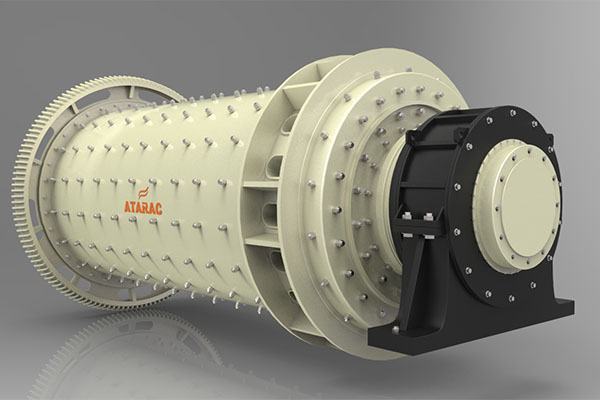

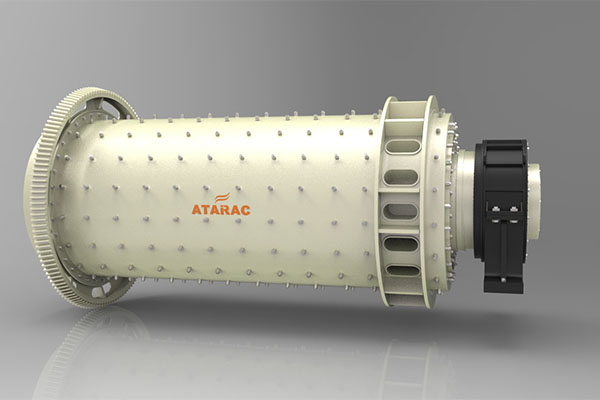

Mill Machine

Home

> Products

> Mill Machine

The rod mill is widely applied to metal and nonmetal mine, water conservancy and glass building materials, grinding various ore, rock and artificial sand which needs product granularity evenly, as well as industry that need little powder in the end products, such as artificial sand, glass raw materials and quartz sand, coal slurry in chemical industry.

1. Our company’s ball mill use rolling bearing instead of sliding bearing, which save 10%-20% of the energy and at the condition of some power, the capacity is 10%-20% higher;

2. The expensive GXYZ is needless when the ball mill lubricated by oil grease instead of thin oil station;

3. Mine ball mill whose diameter over 2700mm can use high pressure motor, pneumatic clutch, gear oil grease lubrication device and low speed driving device for the convenience of turning and repair. These device is optional based on the needs of users;

4. Energy saving by 40% compared with traditional type. The end products granularity is evenly, big granularity and sludge content is less;

5. The contact of ore and ore media is line contact during the grinding, which makes the grinding selectively, the granularity is evenly, over crushing powder content is less. When it applied in primary crusher, the capacity is higher than other rod mill with same model.

| Model |

Barrel Size(㎜) |

Barrel volume(m3) |

Ball load (t) |

Barrel rotating speed(r/min) | Power(kw) | Output size(㎜) | Capacity(t/h) | Weight (t) |

| Dia.* length | ||||||||

| GMB1530 | φ1500×3000 | 5.0 | 8 | 23 | 75 | 2.5-0.2 | 12-5.5 | 16.71 |

| GMB1830 | φ1800×3000 | 6.5 | 17 | 22.8 | 132 | 2.5-0.2 | 20-9.5 | 29.8 |

| GMB2122 | φ2100×2200 | 6.7 | 18 | 20.9 | 160 | 2.5-0.2 | 27-12 | 42.5 |

| GMB2130 | φ2100×3000 | 9.2 | 25 | 20.9 | 160 | 2.5-0.2 | 30-13 | 43.9 |

| GMB2136 | φ2100×3600 | 11.0 | 28 | 20.9 | 200 | 2.5-0.2 | 35-14.8 | 49.4 |

| GMBZ2136 | φ2100×3600 | 11.0 | 32.5 | 20.9 | 210 | -5.0 | 61.5-43 | 49.9 |

| GMB2140 | φ2100×4000 | 12.2 | 31 | 20.9 | 220 | 2.5-0.2 | 38-17 | 50.3 |

| GMB2145 | φ2100×4500 | 13.8 | 35 | 20.9 | 250 | 2.5-0.2 | 43-19 | 51.8 |

| GMB2430 | φ2400×3000 | 12.2 | 31 | 19 | 250 | 2.5-0.2 | 47-22 | 56.0 |

| GMBZ2430 | φ2400×3000 | 12.2 | 31 | 19 | 250 | -5.0 | 73-52 | 58.3 |

| GMB2436 | φ2400×3600 | 14.6 | 37 | 19 | 280 | 2.5-0.2 | 55-26 | 61.0 |

| GMBZ2436 | φ2400×3600 | 14.6 | 37 | 19 | 280 | -5.0 | 84-60 | 62.4 |

| GMB2730 | φ2700×3000 | 15.3 | 35 | 17.5 | 315 | 5-0.8 | 125-37.5 | 75.6 |

| GMB2736 | φ2700×3600 | 18.4 | 42 | 17.5 | 355 | 5-0.8 | 150-45 | 81.8 |

| GMBZ2740 | φ2700×4000 | 20.5 | 47 | 17.5 | 400 | 5-0.8 | 165-50 | 84.3 |

| GMB3040 | φ3000×4000 | 25.9 | 50 | 16.2 | 500 | 5-0.8 | 206-62 | 130 |

| GMB3245 | φ3200×4500 | 33 | 56 | 15.5 | 630 | 5-0.8 | 228-70 | 138 |

| GMB3248 | φ3200×4800 | 34 | 60 | 15.5 | 710 | 5-0.8 | 240-74 | 142 |

| GMB3645 | φ3600×4500 | 40.8 | 78 | 14.5 | 800 | 5-0.8 | 270-83 | 168 |

| GMB3654 | φ3600×5400 | 50 | 94 | 14.5 | 1000 | 5-0.8 | 340-103 | 192 |

The electromotor drives the cylinder to rotate through reduction gear. Under the friction force and centrifugal force the crushed ores inside the cylinder and the steel rod are lifted to a certain height by the lining plate and fall down. The ores are gradually crushed by impacting and grinding, and finally are discharged from the cylinder.

Leave message

Please Feel free to give your inquiry in the form below.We will reply you in 24 hours.