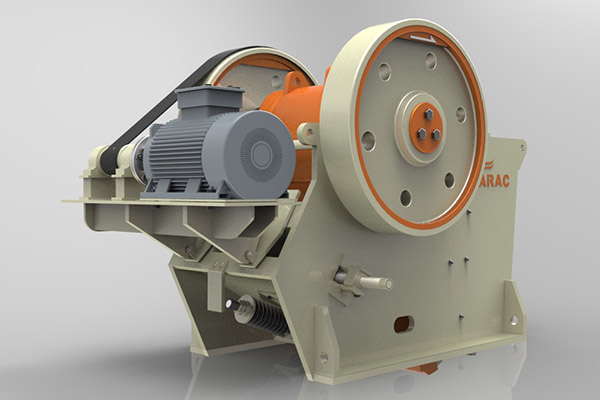

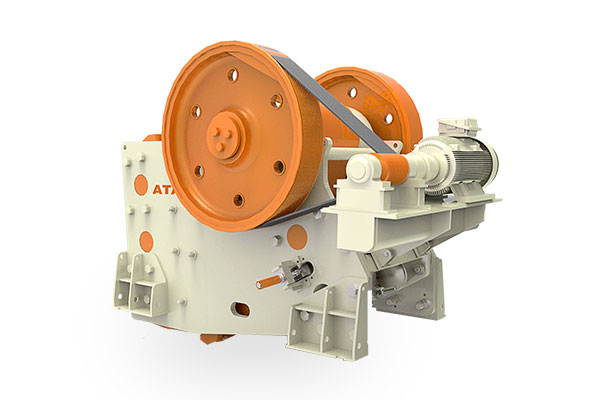

JC Series Jaw Crusher is a new generation jaw crusher with optimized design, which is based on absorbing the international advanced crushing technology. It is the preferred equipment for coarse crushing of various types of rocks.

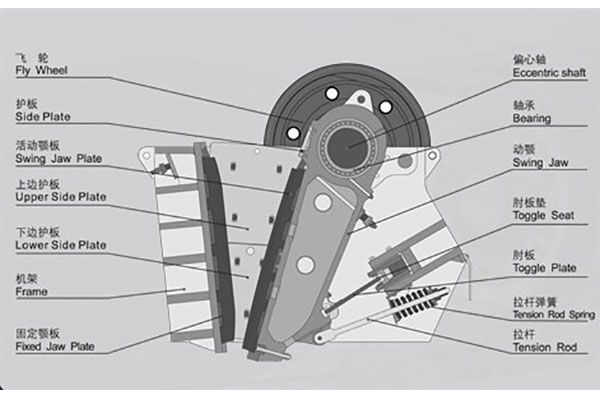

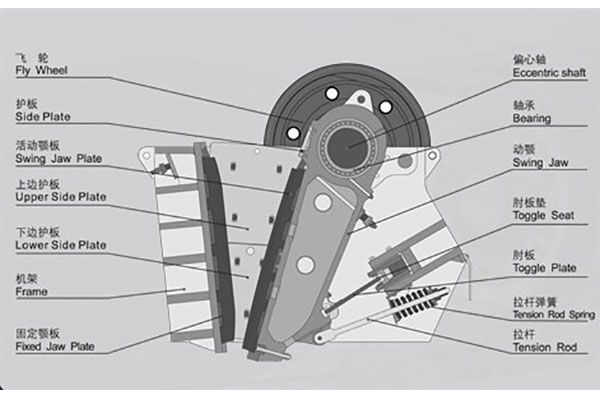

In order to have the excellent stability, JC jaw crusher adopts high-quality casting steel structure, and equips with the large type casting fly wheel, heavy loading eccentric shaft and more larger and durable ball shape rolling bearing.

According to the material, JC Series Jaw Crusher can choose different types of high manganese steel jaw plate.

JC Jaw crusher adopts double wedge blocks adjustment system, which is simple, safe and convenient.

1. High-strength design ensures long life time of frame.

2. The whole set of heavy type swing jaw is more durable.

3. V-Type Deep Crushing Chamber design features in Small nip angle and high reduction ratio which provide throughput 30% more and power consumption 10% to 15% less compared with the traditional crusher.

4. Adopted optimized four-bar linkage, the machine possesses higher rotate speed, longer stroke, better running, so as to maximize its efficiency.

5. By adopting Kinematics Simulation Analysis to Achieve Dynamic Equilibrium, the machine runs stably with small vibration.

6. One piece of steel-cast bearing seat.

7. Hydraulic Double Wedge Blocks to adjust discharge opening.

8. Unique installation design integrates motor and main frame, which reduce installation space and save civil work expense.

9. Unique lubrication system.

10. Temperature and rotate speed sensor, material level detective system in crushing chamber are optional.

11. High utilization rate of jaw plate, less consumption of materials and power.

Model

| Input Opening (mm) |

Max. input Size (mm) |

Discharge Opening (mm)/Capacity(t/h) | Power (kw) | |||||||||||||

| 70 | 80 | 90 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 | 300 | |||||

| JC90 | 910*630 | 530 | 105 | 125 | 145 | 165 | 185 | 235 | 285 | 335 | 90 | |||||

| 140 | 165 | 195 | 220 | 245 | 310 | 375 | 440 | |||||||||

| JC110 | 1100×850 | 720 | 180 | 200 | 220 | 245 | 300 | 350 | 400 | 460 | 110 | |||||

| 240 | 265 | 295 | 320 | 385 | 455 | 520 | 590 | |||||||||

| JC125 | 1250×950 | 810 | 270 | 325 | 385 | 445 | 500 | 560 | 620 | 160 | ||||||

| 360 | 430 | 505 | 580 | 650 | 725 | 800 | ||||||||||

| JC140 | 1400×1070 | 910 | 360 | 425 | 490 | 555 | 625 | 690 | 725 | 200 | ||||||

| 470 | 555 | 640 | 725 | 815 | 900 | 985 | ||||||||||

| JC160 | 1600×1200 | 1020 | 490 | 560 | 635 | 710 | 780 | 855 | 930 | 250 | ||||||

| 640 | 730 | 825 | 920 | 1010 | 1105 | 1200 | ||||||||||

| JC210 | 2100×1600 | 1360 | 800 | 900 | 1000 | 1010 | 1200 | 1300 | 400 | |||||||

Electrical motor drives the belt wheel to make the swing jaw move following the specific track by eccentric shaft. After the materials enter into the crushing chamber, they are crushed between the two jaw plates by impacting, bending, and striking, and then discharged from the discharge opening.

Leave message

Please Feel free to give your inquiry in the form below.We will reply you in 24 hours.