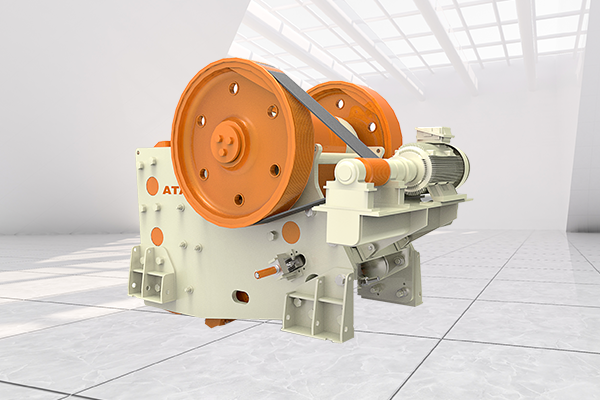

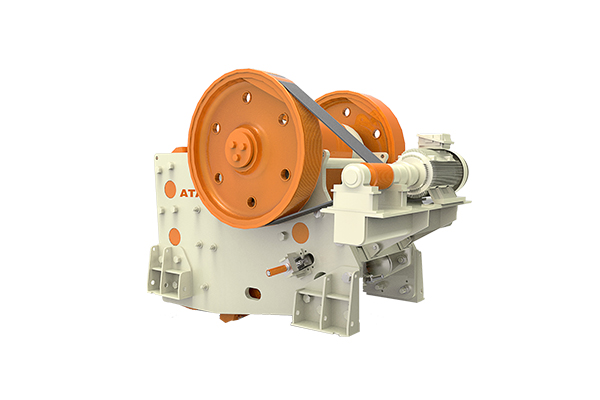

JC Series Jaw Crusher

Max. Feed Size: 720-1360 (mm)

Feed Opening Size: 100×850,1250×950,1400×1070,1600×1200,2100×1600(mm)

Application Fields: metallurgy, mining, chemical, cement, construction, etc.

Applied Material: ore with compression strength less than 300Mpa, rock, slag, etc.

Tel.: (86)-021-38226566 E-Mail: [email protected]

Description

The JC series Jaw Crusher is a new type of jaw crusher with optimized and developed design on structure, material selection, manufacture process and assembly, which is based on absorbing the international advanced technology and applying company’s decades design concept and technology of jaw crusher. With the features of smart structure and excellent performance, JC jaw crusher is suitable for crushing all kinds of hard and abrasive rock and mineral ore. In order to meet the needs of different working conditions from the customers, JC jaw crusher can apply modular bolt connecting frame without welding.

Features

- The structure design is suitable for crushing different kinds of minerals.

- Optimal design of kinematics parameter and crushing chamber increase processing capacity and crushing performance.

- The wedge adjustment for CSS achieves infinite adjustment, which is quick and convenient.

- The bearing design ensures the big loading capacity and reliable operation of jaw crusher.

- The design of toggle plate increases the stroke of lower chamber and processing capacity.

- The integrated design of the motor base together with the main frame saves the installation space.

- In order to increase JC jaw crusher crushing performance, various jaw plate tooth-shapes are suitable for different crushing materials.

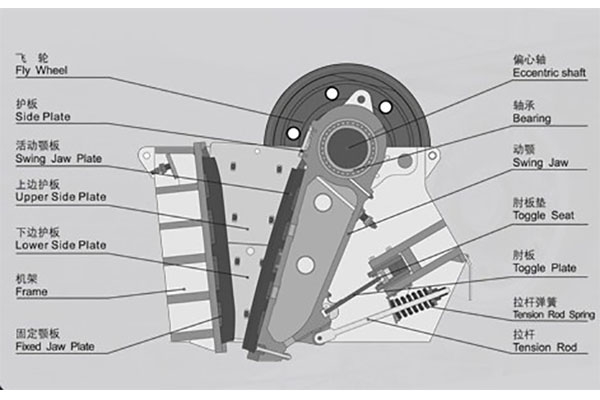

Working Principle

When JC jaw crusher works, electrical motor drives the belt wheel to make the swing jaw move following the specific track by eccentric shaft. After the materials enter into the crushing chamber, they are crushed between the two jaw plates by impacting, bending, and striking, and then discharged from the discharge opening.

Technical Specification

| Model | Feed Opening (mm) |

Max. Feed Size (mm) |

CSS(mm) / Throughput Capacity(t/h) | Power (kW) |

||||||||||||||

| 40 | 50 | 60 | 70 | 80 | 90 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 | 300 | ||||

| JC80 | 800×510 | 430 | 50 | 55 | 80 | 90 | 110 | 120 | 135 | 170 | 200 | 240 | 75 | |||||

| 70 | 85 | 100 | 125 | 145 | 170 | 185 | 240 | 280 | 330 | |||||||||

| JC90 | 910×630 | 530 | 90 | 105 | 115 | 135 | 150 | 170 | 200 | 230 | 275 | 90 | ||||||

| 130 | 140 | 165 | 185 | 200 | 240 | 270 | 300 | 345 | ||||||||||

| ∗ JC96 | 930×580 | 480 | 105 | 125 | 140 | 160 | 175 | 220 | 265 | 310 | 90 | |||||||

| 135 | 155 | 180 | 200 | 225 | 285 | 335 | 390 | |||||||||||

| ∗ JC106 | 1060×700 | 590 | 150 | 160 | 190 | 205 | 255 | 305 | 355 | 395 | 110 | |||||||

| 185 | 215 | 235 | 265 | 325 | 385 | 450 | 500 | |||||||||||

| ∗ JC116 | 1150×760 | 640 | 165 | 180 | 205 | 225 | 270 | 320 | 370 | 410 | 110 | |||||||

| 205 | 235 | 255 | 285 | 345 | 405 | 465 | 520 | |||||||||||

| JC100 | 1000×760 | 640 | 140 | 150 | 170 | 190 | 230 | 280 | 330 | 370 | 110 | |||||||

| 170 | 195 | 215 | 255 | 300 | 350 | 420 | 480 | |||||||||||

| JC110 | 1100×850 | 720 | 180 | 200 | 220 | 245 | 300 | 350 | 400 | 460 | 110 (132) |

|||||||

| 240 | 265 | 295 | 320 | 385 | 455 | 520 | 590 | |||||||||||

| JC125 | 1250×950 | 810 | 270 | 325 | 385 | 445 | 500 | 560 | 620 | 160 | ||||||||

| 360 | 430 | 505 | 580 | 650 | 725 | 800 | ||||||||||||

| JC130 | 1300×1000 | 850 | 350 | 415 | 480 | 540 | 605 | 670 | 715 | 185 | ||||||||

| 460 | 545 | 625 | 700 | 785 | 865 | 960 | ||||||||||||

| JC140 | 1400×1070 | 910 | 360 | 425 | 490 | 555 | 625 | 690 | 725 | 200 | ||||||||

| 470 | 555 | 640 | 725 | 815 | 900 | 985 | ||||||||||||

| JC160 | 1600×1200 | 1020 | 490 | 550 | 635 | 710 | 780 | 855 | 930 | 250 | ||||||||

| 640 | 730 | 825 | 920 | 1010 | 1105 | 1200 | ||||||||||||

| JC180 | 1800×1500 | 1280 | 650 | 730 | 810 | 930 | 1000 | 1150 | 355 | |||||||||

| 880 | 960 | 1050 | 1160 | 1300 | 1400 | |||||||||||||

| JC210 | 2100×1600 | 1360 | 800 | 900 | 1000 | 1100 | 1200 | 1300 | 450 | |||||||||

| 880 | 1005 | 1125 | 1225 | 1375 | 1500 | |||||||||||||

| JC1613 | 1600×1300 | 1110 | 590 | 665 | 745 | 820 | 900 | 975 | 280 | |||||||||

| 765 | 865 | 965 | 1060 | 1160 | 1260 | |||||||||||||

| JC2012 | 2000×1200 | 1020 | 600 | 650 | 700 | 870 | 950 | 1100 | 355 | |||||||||

| 730 | 830 | 900 | 1100 | 1250 | 1400 | |||||||||||||

Remark:

1.The capacity listed from the table is the corresponding parameters to crush the rock with the loose density of 1.6t/m³ (a feed material with an average specific gravity of 2.7t/m³).

2.The processing capacity shall be changed according to the different materials and different feeding.

3.The CSS refers to Closed Side Setting. The measuring method will be decided by the tooth profile of the jaw plates.

4.The processing capacity and the product size shall be changed according to the different tooth profile.

5.The model parameters marked with ∗ are the parameters of the mobile crushing station special jaw crusher.